Commercial Water Purification

One-Stop Solution for All Types of Commercial Water Purifiers

Swimming Pool Sand Filter System

400G Commercial RO Water Dispenser With 4 Faucet

400G Commercial RO Water Dispenser With 2 Faucet

600G Commercial RO Water Dispenser

Customized Commercial Water Purification Solutions

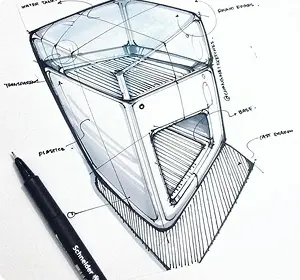

Design Options - Standard vs. Tailored Models

RO Membrane Filtration - High Precision & Durability

Multi-Stage Filtration - Comprehensive Protection

How We Craft Premium Water Purification

Design & R&D

Component Production

Surface Treatment & Integration

Final Assembly & Certification

Advanced Quality Control & Testing

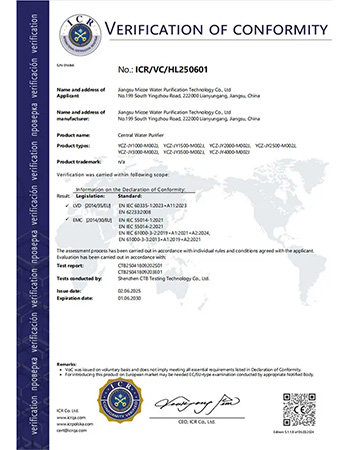

Qualification Certification

Trusted Water Purification Brands Worldwide

Trusted by

Our Most Frequently Asked Questions

A stable power socket that is suitable for the machine’s voltage needs to be reserved. A proper water source interface should be prepared to ensure that the inlet water pressure is between 0.1-0.4MPa. Sufficient installation space should be reserved. An area of 10-15cm around the machine should be left for subsequent maintenance, and the installation location should be away from areas with high temperature, humidity, and strong electromagnetic interference.

After connecting the water source and power supply, open the inlet water valve and observe whether there is any water leakage in the machine. Then turn on the machine and let it automatically flush the filter element for 15 – 20 minutes to discharge the protective liquid and impurities in the filter element. After the flushing is completed, check the quality of the outlet water. You can use a water quality testing pen to measure the TDS value. If the value is below 50ppm and the outlet water has no peculiar smell and no foam, it means that the debugging is normal and the water purifier can be put into use.

Although the vertical direct drinking machine is designed to meet the needs of a large number of people, continuous high-load operation for a long time will increase the wear and tear of the machine. It is recommended to let the machine stop running for 15 – 30 minutes every 4 – 6 hours to facilitate heat dissipation and the recovery of internal components and extend the service life of the machine.

It doesn’t need to be on 24 hours a day. Energy-saving techniques are crucial.

In terms of space, the total floor area of the entire unit is ≤ 1.5㎡, and a 0.3m operating space should be reserved.