Product Description

Technical Specifications & Models

| Inlet and outlet | three eighth inch | Voltage (V)/Power | 100-240V 50Hz-60Hz/3KW |

|---|---|---|---|

| Applicable water temperature | 41-100˚F/5˚c-38˚c | RO water flow | 1.5L/min |

| Hot/Normal water flow | 3.0L/min | Inlet pressure | 0.1MPa-0.35MPa |

| Operating Pressure | 0.6MPa-0.8MPa | Rated water capacity | 4000L |

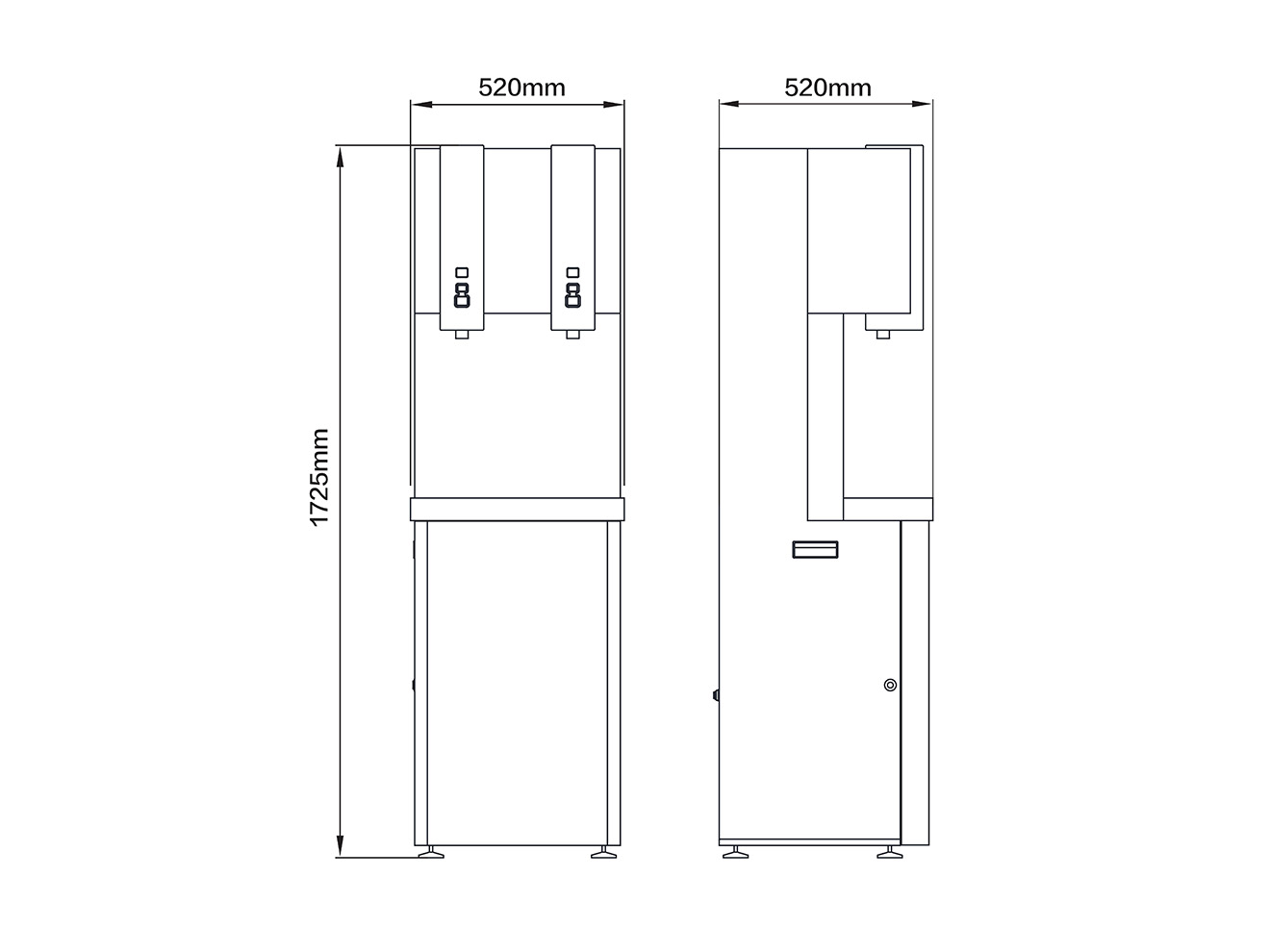

| Product dimension/mm (L*W*H) | 520×520×1725(mm) | Packing dimension/mm (L*W*H) | 570×590×1730 |

| Hot water tank | 42L | Pure water tank | 11G |

| Water Dispenser | Normal Temp. water and hot water | Applicable water source | Municipal Tap water |

Why choose 600G Commercial RO Water Dispenser

Hot and cold water output

Intelligent display

Self-cleaning

High water intake

Convenient filter element replacement

UVC-LED sterilization

Ideal For Your Industry

Frequently Asked Questions

It needs to be installed on a stable and dry ground. At least 50cm of space should be reserved around it for heat dissipation, maintenance, and operation by personnel. A stable power socket is required, and the circuit should be well grounded. At the same time, it should be close to the municipal water supply pipeline and drainage pipeline. The inlet water pressure should be maintained at 0.1 – 0.4MPa. If the water pressure is insufficient or too high, a booster pump or pressure reducing valve needs to be installed.

After connecting the water source and power supply, open the inlet water valve and observe whether there is any water leakage in the machine. Then turn on the machine and let it automatically flush the filter element for 15 – 20 minutes to discharge the protective liquid and impurities in the filter element. After the flushing is completed, check the quality of the outlet water. You can use a water quality testing pen to measure the TDS value. If the value is below 50ppm and the outlet water has no peculiar smell and no foam, it means that the debugging is normal and the water purifier can be put into use.

Although the vertical direct drinking machine is designed to meet the needs of a large number of people, continuous high-load operation for a long time will increase the wear and tear of the machine. It is recommended to let the machine stop running for 15 – 30 minutes every 4 – 6 hours to facilitate heat dissipation and the recovery of internal components and extend the service life of the machine.